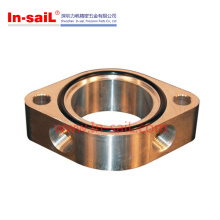

Inserciones roscadas de presión para el caso principal

Información básica

Modelo: Metric, Inch, DIN, OEM

Descripción del producto

Tipo: Cabeza redonda Estilo principal: Ronda Grado: 3.6 Acabado: Zn / Ni / Tin / Au que platea, óxido negro, anodizando y tan Certificación: SGS, RoHS, material Certication, muestras de Ppap : Bienvenido Especificación: SGS, Certificación de materiales Código HS: 7318160000 Material: Latón Conexión: Perno común Estándar: DIN, ANSI, GB, JIS, GOST, BSW Nombre del artículo: Sistema de gestión de inserciones roscadas: ISO9001: Días Marca registrada: In-saiL Origen: Shenzhen, China Prensa-Fit roscó inserta para el caso principal

Perfil de la compañía

La calidad es nuestra cultura

Un socio de confianza

In-saiL se dedica a la fabricación de componentes de precisión y el diseño, fabricación de sujetadores de ingeniería de especialidad y el desarrollo de la solución de fijación y período;

Capacidad de fabricación

Contamos con una potente capacidad de fabricación, nuestros tornos automáticos, tornos CNC, centros de mecanizado CNC, máquinas de estampado y máquinas de arranque en frío, además de equipos auxiliares como fresadora, rectificadora, EDM y la cooperación de nuestros socios, Del prototipado o serie de producción y período;

En-vela & sol; Sandum se dedica a la fabricación de componentes de precisión y el diseño, la fabricación de sujetadores de especialidad de ingeniería y el desarrollo de la solución de fijación & período;

Capacidad de fabricación

Tenemos una capacidad de fabricación de gran alcance, nuestros tornos automáticos, tornos CNC, centros de mecanizado CNC, máquinas de estampado y máquinas de arranque en frío más equipos auxiliares como fresadora, rectificadora, EDM y la cooperación de nuestros socios, somos capaces de soportar todos los diferentes componentes independientemente Del prototipado o serie de producción y período;

Perfil de la compañía

La calidad es nuestra cultura

Un socio de confianza

In-saiL se dedica a la fabricación de componentes de precisión y el diseño, fabricación de sujetadores de ingeniería de especialidad y el desarrollo de la solución de fijación y período;

Capacidad de fabricación

Contamos con una potente capacidad de fabricación, nuestros tornos automáticos, tornos CNC, centros de mecanizado CNC, máquinas de estampado y máquinas de arranque en frío, además de equipos auxiliares como fresadora, rectificadora, EDM y la cooperación de nuestros socios, Del prototipado o serie de producción y período;

| Material | Brass,Stainless Steel,Carbon steel,Aluminum alloy,according to customer's requirement |

| Finish | Zn/Ni/Tin/Au plating,Black Oxide,Anodizing and so on. |

| Insert Methods | By Ultrasonic,Heat staking,Insert Molding,Cold press-in Methods |

| Quality Control | Follow Drawing Spec |

| Management System | ISO9001:2008 |

| Certification | SGS,RoHS,Material Certication,PPAP |

| Lead Time | 5-10 working days |

| Samples | Welcome |

| Delivery term | By DHL,UPS,TNT,FedEx,EMS,By Ocean,By Air |

| Production Capability | Auto-lathe turning:ODΦ0.5-20mm,Tol.±0.01mm |

| CNC lathe turning:ODΦ0.5-250mm,Tol.±0.005mm | |

| CNC Milling:800x600mm(LxW),Tol.±0.05mm | |

| Grinding:Tol.±0.002mm | |

| Screw heading & rolling:Metric 0.8-M6,Unified Imperial#0-1/4'' | |

| Stamping:200T max |

En-vela & sol; Sandum se dedica a la fabricación de componentes de precisión y el diseño, la fabricación de sujetadores de especialidad de ingeniería y el desarrollo de la solución de fijación & período;

Capacidad de fabricación

Tenemos una capacidad de fabricación de gran alcance, nuestros tornos automáticos, tornos CNC, centros de mecanizado CNC, máquinas de estampado y máquinas de arranque en frío más equipos auxiliares como fresadora, rectificadora, EDM y la cooperación de nuestros socios, somos capaces de soportar todos los diferentes componentes independientemente Del prototipado o serie de producción y período;

| We are the leading manufacturer of Brass threaded inserts for plastics industries, communication equipments, automotive industries, electrical & Wiring device cases etc. We offer a full line of brass inserts for all methods of installation, including: ultrasonic, heat, thermal, press-in and mold-in. Although we produce various brass inserts as per custom design & specification, we have standard series of Threaded Inserts such as Straight Hole, Blind (Closed bottom), Collar Inserts, Ultrasonic, Press in, Tri Slotted Inserts etc. Around 3.5 million pieces of variety of brass inserts are manufactured by us per month to cater the voluminous demand of all our giant OEMS around the globe. Material: Generally Free Machine Grade of CuZn37Pb3 equivalent to BS 2874 is used to manufacture various brass inserts in form of round, Hexagon, Square etc. Other grades which are followed as per custom requirements are CZ 121, CZ 131, C3604, CDA 360 and DTD 627 etc. Key Features: ? Thread Size Starts from M1.6 to M50. BA, BSW, BSPT, BSF & American Threads like UNC, UNF, UNEF and NPT are also available as per custom requirements. ? Straight, Diamond, opposite diagonal etc. are the knurling options available to give solid gripping to Molding applications. ? Inserts available as per Class 2B ANSI/ASME B1.1 & Confirms to ISO metric 6H Thread Standards. ? Inserts with collar series provides Options to use Flange to make Electric Contact. ? Ultrasonic series with Opposing Diagonal Knurls provide excellent Torque Resistance Vertical Undercuts in Tri Series Provides Superior Tensile Strength ? Blind thread or closed bottom Inserts prevents plastic from entering the bottom of the insert. Finish: Generally Brass Inserts comes with the Natural, Nickel & Tin Finish. But Surface Finishes such as Chromium, Silver, Gold, etc. can be done as per customers requirement. | |

| Brass Threaded Inserts | |

| Brass Knurled Inserts | |

| Brass Inserts for Plastics | |

| Brass Inserts for Wood and Clipboard | |

| Ultrasonic range of Brass Inserts | |

| Heatbit range of Brass Inserts | |

| Press-in Inserts with and without collars | |

| Molded-in Inserts | |

| Also Available : | |

| Brass Round Knurled Inserts Brass Hexagonal Inserts Brass Square Inserts |

|

| Special Features of Brass Inserts: | |

|

Threads as per International Go & Not Go Standards. Deep Groove for maximum Pull Out Resistance. Inner Diameter (I/D) after Threads with very close tolerance to prevent unnecessary flush to enter into the brass inserts. Knurling Available : Diamond Straight Unidirectional Both blind and through brass inserts are available with no minimum Qty. |

|

| Length / Size : | |

|

Begins from M2 or equivalent threads and up to any size as per custom design or requirement |

|

| Typical Application : | |

|

Instrumentation, Telecommunications, and other Plastic Cases Assembly. |

|

| Threads : | |

|

ISO Metric (MM Threads) BA, BSW (Inches), UNC, UNF or Any as per custom design |

|

| Material : | |

|

Free Cutting Brass IS 319 Type (I) or BS 249 Type (I) or High Grade Any Special Brass Material Composition as per customers requirement |

|

| Finish And Coating : | |

| Natural, Nickle Plated, Tin Plated brass inserts or any coating as per customer specification. | |

| Any kind of special brass inserts can be developed and supplied exactly as per customer specifications. | |

Grupos de Producto : Intsert tuercas para plasticos > Serie de inserciones roscadas de presión.

Otros productos

Productos hot

ANSI ASME perno de la pistaT5 T10 T15 T20 T25 T30 T40 T35 tornillo torx de accionamientoTornillo de ojo de acero inoxidableBulk Buy From China America Camión Venta caliente grado 8.8 / 10.9 Bolso del eje de ruedaProveedor de China alta calidad negro acabado de acero cabeza cuadrada pernoFabricación Certificado ISO9001: 2008 Popular en Europa U Bolt With Good ServidePerno CALIENTE CALIENTE de la pista CALIENTE y tuerca en grado 8.8 y 10.9el tornillo de la máquinaAlibaba en línea de compras de acero al carbono amarillo cincado T cabeza pernoCable del alambre del surtidor de China, SAE1008 Barra del alambre de acero con buen precioChina proveedor acero al carbono cabeza doble tornillo prisioneroProveedor de hardware tornillo hexagonal enchapado en zinc de acero al carbonoAlibaba proveedor de hardware de acero suave de zinc galvanizado brida pernoProveedor de hardware A193 B7 perno prisionero de óxido negro con tuercaAlibaba en línea proveedor negro cincado de acero al carbono pernos de carro304 Perno y tuerca de acero inoxidable